![REFINISH3 POLISHING COMPOUND REFINISH3 POLISHING COMPOUND]()

Item number : PN.R-2003

Common Uses : All exterior vehicle surfaces which can be polished.

Net content : 250ml, 1000ml

Theory of Refinish Series

![REFINISH3 POLISHING COMPOUND REFINISH3 POLISHING COMPOUND]()

Diagram 1 | ![REFINISH3 POLISHING COMPOUND REFINISH3 POLISHING COMPOUND]()

Diagram 2 |

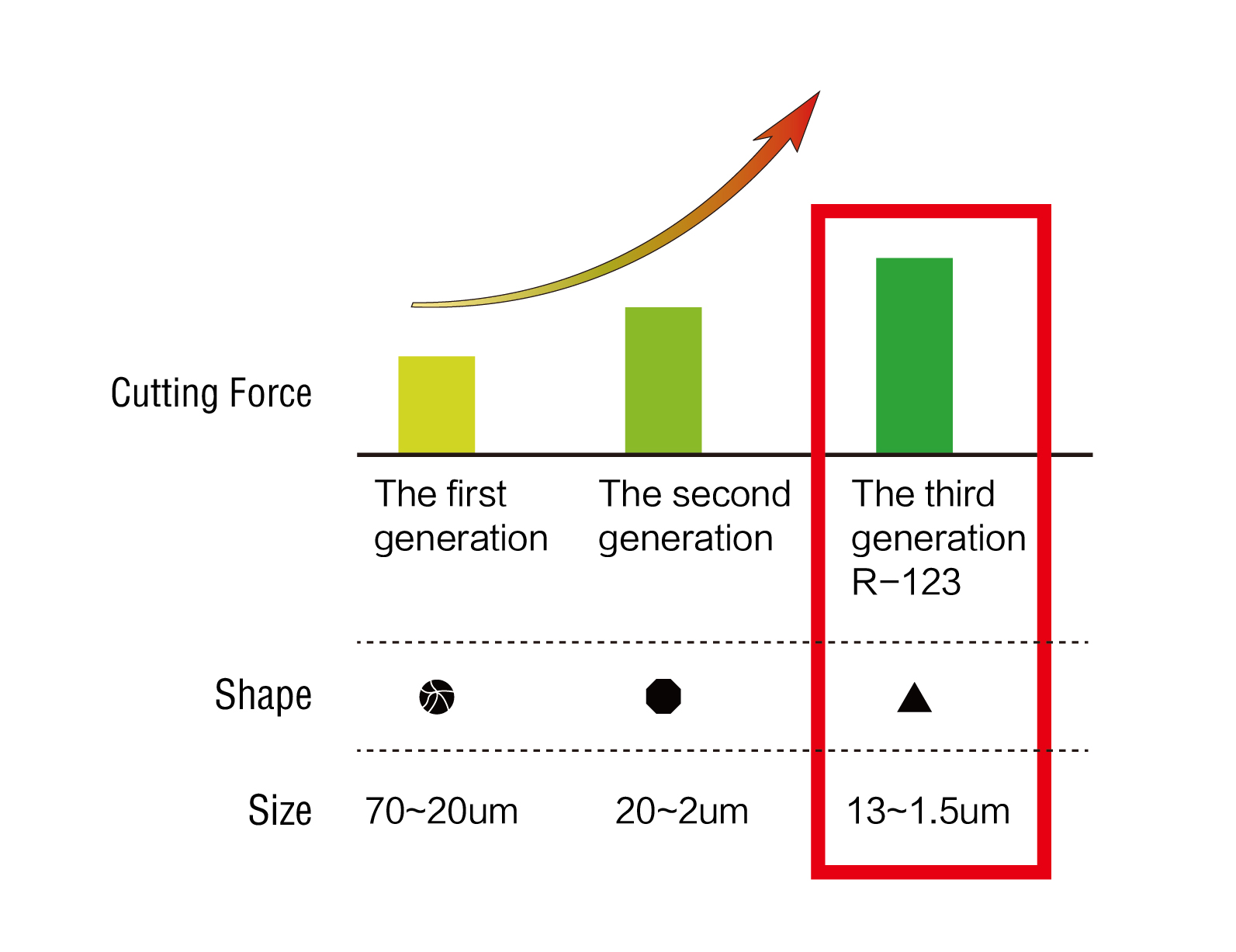

As highlighted by Figure 1, the polishing compounds have developed the style of the abrasive from its original irregular shape that easily crumbled during polishing work times. The issue with these broken abrasive pieces was often damage to the paint surface. The size of this first generation polishing compounds varied between 70~20µm. when operating on the paint surface, for best performance, the user needed to use from big sized particles to the small particles sequentially. If did not apply step by step from the small size polishing compound as the last step, there will left big swirl marks on the paint work. But even so, it still difficult to clean the swirl mark perfectly. The second generation of polishing compound adopted an octagon shape. Developed accordingly to prevent the abrasive from breaking and damaging the paint surface during the polishing time. The size of the abrasive of the second generation polishing compound varied between 20 to 2µm, and was also required to be used sequentially, in order to remove the swirl marks. However, as with the previous generation it had difficulty for removing the swirl marks clean.

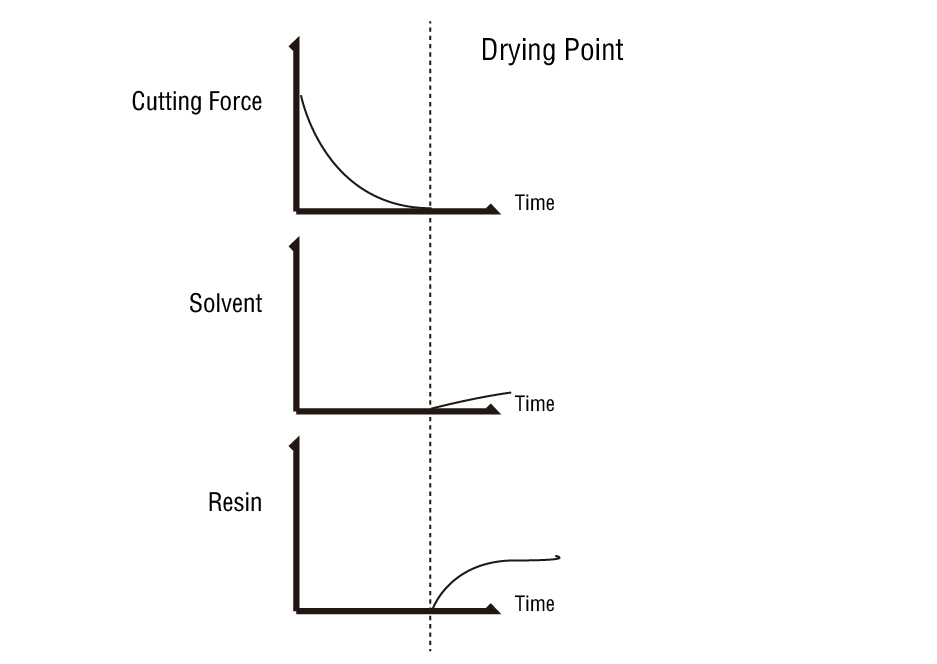

The first and second generation polishing compounds are oil-based, and many other companies have not developed beyond this second generation stage. TAC has manufactured the third generation of polishing compound, the series of Refinish 1, 2 and 3. R1, 2 and 3 are using on the water-based paint surface and have adopted a tetrahedron shape for the abrasive. If taken from the front, it looks triangle in shape. This innovative design creates a stronger cutting force then the past generations of the polishing compound. The cutting force of Refinish series will decrease until the water dries out, eventually becoming zero. There are resins contented in the R1, 2, and 3, at the point in time for water dries out, the solvent will come out and the resin will enclose all around the triangles, let them become smoothly and do not hurt the paint surface, shown as in the picture 2.

![REFINISH3 POLISHING COMPOUND REFINISH3 POLISHING COMPOUND]()

Why your car needs polishing?

In the picture 3 we can see that, there are three basic layers of the paint surface, the primer layer, color layer and the clear coat. When there is dirt, scratches, and other contaminants on it, the paint surface will not so glossy. Usually these scratches, dirt and contaminants are on the clear coat. When our eyes accept more reflected rays from the surface, then it is more shine. After polishing work, the surface will become clean and smooth, therefore the direction of most reflection lights will be same, and from visual perception it is glossy.

Usually the scratches are on the clear coat, after polishing work will remove them. Of course some scratches have hurt the color layer, if so you should take other steps.

![REFINISH3 POLISHING COMPOUND REFINISH3 POLISHING COMPOUND]()

Product Description:

TacSystem’s Refinish 3 is formulated polishing and glazing compound especially for water based paintwork. Refinish3 produces an extreme gloss finish and it can be remove fine swirl marks holograms. Refinish 3 finest polish for all paint finishing needs. While it was designed as a polish, R3 can tackle much heavier defects than traditional polishes. Refinish3, as a finish polish, leaves a surface free of fine defects and micro-marring and leaves paint super glossy and reflective.

Product Benefits:

Refinish 3 is a paint correction polish formulated with non-diminishing abrasives of both natural resin and highly durable silica particles. Refinish 3 has the ability to remove 2500grit sanding scratches, light topical defects, light water spots, swirl marks and light scratches. Refinish 3 also enhances the level of gloss during the paint correction process. Refinish 3 is a low dusting, silicone free, and body shop safe product.

![REFINISH3 POLISHING COMPOUND REFINISH3 POLISHING COMPOUND]()

Directions:

1. Shake product well before using.

2. Start with a new or clean pad. Used or dirty pads may obtain contaminants that can scratch the surface.

3. Distribute product evenly over the pad surface to ensure all portions of the pad are ready for correction.

Tips / Alternate Uses:

Refinish 3 can be used with Rotary or Dual Action Polishers, or by hand. Clean pads often for best results. Dirty pads being to scour paint when filled up with too much paint residue from the correction process.

![REFINISH3 POLISHING COMPOUND REFINISH3 POLISHING COMPOUND]()

-Keep bottle tightly closed after used and store in cool dry space.

-Keep product out of reach from children.

-Wear suitable gloves. If comes into contact with skin, rinse well with water.

-If it comes in contact with eyes, rinse immediately and seek medical advice.

-Do not drink! If swallowed, consult a doctor immediately and show product container and label.

If you are interested in this item, please contact us by email.

Or if you have any questions or needs about our products, please contact us at any time.

We are also going to export this product all over the world.

제품명 : REFINISH 3

사용처 : 모든 차량 도장면의 광택

용량 : 250ml, 1000ml

Refinish 시리즈의 작용 원리

Diagram 1 |

Diagram 2 |

1세대 화합물의 입자는 불규칙한 형태로 개발되었으나 광택작업 과정에서 쉽게 깨져 도장면에 미세 손상을 입혔습니다. 1세대 입자의 크기는 70~20μm 사이였습니다. 디테일러는 각 패널을 단계별로 작업해야 하는데, 우리는 이를 "전통적인 연마 스타일"이라고 합니다. 1~2단계에서 시작해 3~4단계의 혼합물로 구성될 수 있는 미세화 방식으로 넘어갑니다. 그러나 디테일러는 여전히 표면에 스월마크를 볼 수 있습니다.

1세대와 관련된 문제로부터 제조업체는 분해 시 연마재가 도장을 손상시키는 것을 방지하기 위해 2세대 화합물을 개발했습니다. 2세대 복합물은 20에서 2μm 사이의 8각형 모양을 채택했습니다. 연마 시간과 측정 방법은 1세대와 동일했지만 페인트 보정 시 스월 자국이 쉽게 생성되지 않았습니다.

1세대와 2세대 광택화합물은 모두 석유를 기반으로 했습니다. 대부분의 제조업체가 여전히 2세대 화합물을 생산하고 있을 때, TACSYTEM은 3세대 화합물인 수성 화합물의 개발을 시작했습니다. 정제 시리즈, R1 R2, R3. 이 화합물들은 4면체의 모양을 하고 있으며, 2차원에서 보면 삼각형 모양으로 보일 것입니다. 이 혁신적인 설계는 이전 세대의 광택 화합물보다 훨씬 강력한 연마력을 만들어냅니다. 연마 진행 중에 수분이 마르면 Refinish 시리즈의 연마력이 감소합니다. Refinish 시리즈는 물이 마르면 연마제 입자를 감싸는 레진이 생성되므로 표면에 손상이 발생하지 않습니다. 도표 2와 같은 Refinish 시리즈의 작업 시간 및 성능. 페인트 교정의 진행은 이 세대와 함께 2~3단계로 구성되어 있으나, 광택이 매우 뛰어나고 광택작업시 소요시간이 현저하게 감소되었습니다.

2.

당신의 차는 왜 광택을 내야 할까요?

첫째, 전세계 대부분의 자동차 제조업체에는 두 가지 일반적인 페인트 시스템이 있다는 것을 이해해야 합니다. 일반적인 페인트 시스템은 프라이머 레이어, 컬러 레이어 및 클리어 코팅의 세 가지 기본 레이어로 구성됩니다. 클리어 코팅층은 차를 반짝이는 층으로 보호해 줍니다. 이 층이 오염되거나 먼지, 얼룩 및 긁힘으로 덮여 있는 경우, 그림 2에서와 같이 차량의 반사가 현저하게 감소하여 둔탁함과 매력이 떨어지게 됩니다.

따라서 차를 광택내야 하는 이유는 다른 환경 요인에 의해 발생했을 수 있는 투명 코팅의 결함을 제거하기 위한 것입니다. 그렇지 않으면 먼지가 쌓이고 일부 오염 물질은 부식성이므로 제때 처리하지 않으면 영구적으로 손상될 수 있습니다. 먼지를 제외하고, 긁힌 자국은 차량의 광택에 영향을 미치는 주요 요인 중 하나이며, 상당히 많은 소유자가 세차 장소를 잘못 선택했거나 자동차 관리 제품을 잘못 선택하였습니다! 오염물과 긁힌 자국을 제거하기 위해 디테일러는 다양한 자동차 관리 제품이 필요하며 페인트 표면에 광택을 최대한 내기 위해 시간을 투자합니다.

특징

TACSYSTEM의 Refinish 3은 특히 수성 페인트 작업을 위해 합성된 광택 및 유리 화합물입니다. Refinish3는 극도의 광택 마감 처리 기능을 제공하며, 홀로그램의 미세한 스월마크를 제거할 수 있습니다. 페인트 마감 시 필요한 모든 3가지 최고급 광택제를 마감합니다. R3는 광택제로 설계되었지만 기존 광택제보다 훨씬 더 무거운 결함을 해결할 수 있습니다. 마감 광택제3는 표면에 미세한 결함과 미세 마진을 남기지 않고 페인트를 매우 광택이 나고 반사성이 뛰어난 상태로 남깁니다.

마감 3은 천연 수지 및 내구성이 뛰어난 실리카 입자의 비마이너스 연마재로 제조된 페인트 보정 광택제입니다. Refinish 3은 2500방 샌딩 긁힘, 가벼운 국소 결함, 가벼운 물 얼룩, 소용돌이 자국 및 가벼운 긁힘을 제거할 수 있습니다. 또한 Refinish 3은 페인트 보정 프로세스 중 광택 수준을 향상시킵니다 Refinish 3은 먼지가 적고, 실리콘 무첨가의 안전한 제품입니다.

사용방법

1. 제품을 사용하기 전에 잘 흔드세요.

2. 새 패드 또는 깨끗한 패드로 시작합니다. 사용 중이거나 더러운 패드는 표면을 긁을 수 있는 오염물질이 발생할 수 있습니다.

3. 패드의 모든 부분에 묻을 수 있도록 패드 표면에 제품을 고르게 펴 발라 작업합니다.

Refinish 3 은 로터리 또는 듀얼 액션 폴리셔와 함께 사용하거나 손으로 사용할 수 있습니다. 최상의 결과를 얻으려면 패드를 자주 청소하십시오. 광택 과정에서 나온 페인트 잔여물이 너무 많이 차면 페인트를 문지르는 더러운 패드로 인해 추가 손상이 일어날 수 있습니다.

주의사항

최상의 성능을 위해 직사광선과 뜨거운 도장면 아래에서 작업하는 것을 피하십시오.

도장면에서 건조되지 않도록 하십시오.

도장면을 충분히 식힌 뒤 사용하십시오.

피부에 닿은 경우 물로 잘 헹구어 줍니다.

사용 중에는 항상 마스크와 장갑을 착용하십시오.

눈에 닿으면 즉시 헹구고 의사의 진료를 받으십시오.

삼킨 경우 즉시 의사의 진찰을 받고 제품 용기 및 라벨을 보여줍니다.